Exploring the Process of Custom Thai Silk Factory

Custom Thai silk factories play a crucial role in the production of high-quality silk products, such as silk durags and silk head scarves. These factories are known for their meticulous attention to detail and commitment to producing custom-made silk items that meet the unique needs and preferences of their customers. From selecting the finest silk threads to handcrafting each piece with precision, custom Thai silk factories are dedicated to delivering exceptional quality and craftsmanship.

| barbour scarf | silk rayon | 30mm | 2 meter shawl |

| cotton poplin mixed | bags scarf | best kerchief | a hijab scarf |

| 22mm | cotton canvas blend | no minimun order | silk ties |

The process of creating custom silk products begins with the selection of the raw materials. Thai silk is renowned for its superior quality and luxurious feel, making it the perfect choice for custom-made silk items. The silk threads used in the production process are carefully sourced from reputable suppliers to ensure that only the best materials are used. This attention to detail sets custom Thai silk factories apart from mass-produced silk manufacturers, as they prioritize quality over quantity.

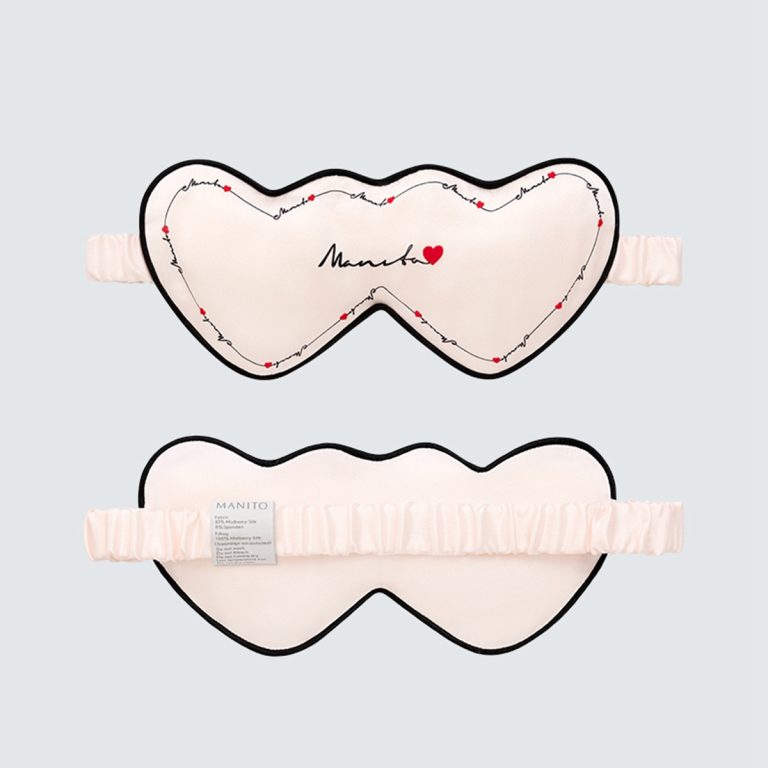

Once the raw materials have been selected, the next step in the process is the design phase. Customers have the opportunity to work closely with the factory’s design team to create a custom design that reflects their personal style and preferences. Whether it’s a custom silk durag or a silk head scarf, the design team will work tirelessly to bring the customer’s vision to life. From choosing the color and pattern to deciding on the size and shape, every detail is carefully considered to ensure that the final product meets the customer’s expectations.

After the design has been finalized, the production process begins. Skilled artisans at the custom Thai silk factory use traditional techniques and modern technology to handcraft each piece with precision and care. From weaving the silk threads to dyeing the fabric and adding finishing touches, every step of the production process is carried out with the utmost attention to detail. This dedication to craftsmanship ensures that each custom silk item is of the highest quality and will stand the test of time.

Once the production process is complete, the final product is carefully inspected to ensure that it meets the factory’s strict quality standards. Any imperfections or flaws are addressed and corrected before the product is packaged and shipped to the customer. This commitment to quality control is what sets custom Thai silk factories apart from other manufacturers, as they strive to deliver only the best silk products to their customers.

In conclusion, custom Thai silk factories are dedicated to producing high-quality silk products that are custom-made to meet the unique needs and preferences of their customers. From selecting the finest silk threads to handcrafting each piece with precision, these factories prioritize quality and craftsmanship above all else. By working closely with customers to create custom designs and using traditional techniques to produce each item, custom Thai silk factories ensure that every silk product is a true work of art. Whether it’s a custom silk durag or a silk head scarf, customers can trust that they are receiving a product that is made with care and attention to detail.