The Art of Printing on Silk Turbans

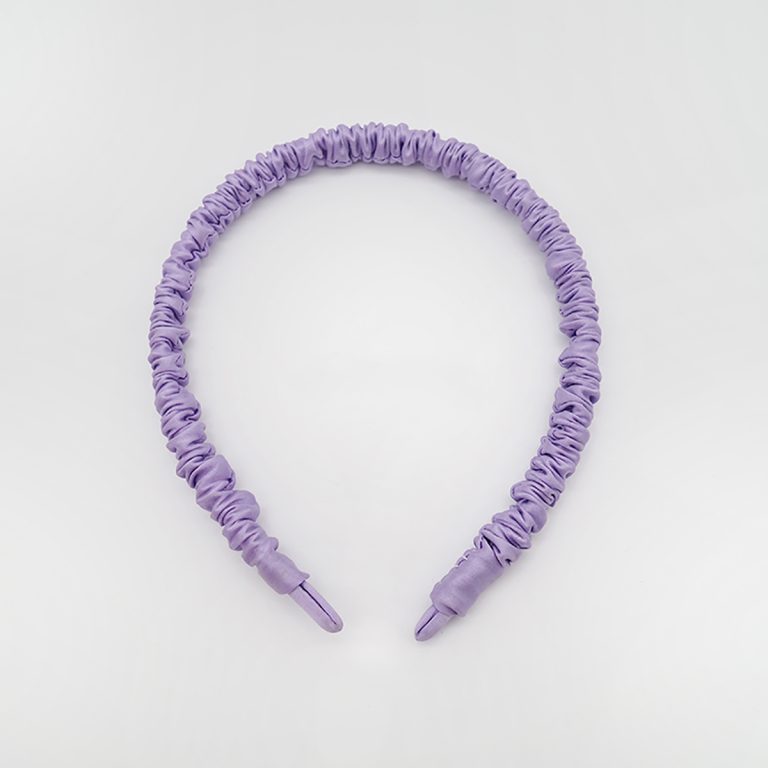

Silk turbans have been a staple in many cultures for centuries, serving as a symbol of elegance, sophistication, and tradition. The art of printing on silk turbans has evolved over time, with modern techniques and technologies allowing for intricate designs and vibrant colors to be applied to this luxurious fabric.

Printing on silk turbans requires a delicate touch and a keen eye for detail. The process begins with selecting the right type of silk fabric, as different weaves and weights can affect the final outcome of the print. Once the fabric is chosen, the design is carefully transferred onto the silk using specialized printing techniques.

One of the most common methods of printing on silk turbans is screen printing. This technique involves creating a stencil of the design and then using a squeegee to push ink through the stencil onto the fabric. Screen printing allows for precise and detailed designs to be printed on silk turbans, making it a popular choice for many designers and manufacturers.

Another popular method of printing on silk turbans is digital printing. This technique involves using a computer-controlled printer to apply the design directly onto the fabric. Digital printing allows for complex patterns and vibrant colors to be printed on silk turbans with ease, making it a versatile option for designers looking to create unique and eye-catching designs.

In addition to printing, silk manufacturers also play a crucial role in the production of silk turbans. Silk is a delicate and luxurious fabric that requires careful handling and expert craftsmanship to ensure a high-quality end product. Silk manufacturers work closely with designers and printers to source the best quality silk fabric and ensure that the final product meets the highest standards of quality and craftsmanship.

Silk manufacturers also play a key role in the dyeing process of silk turbans. Dyeing silk requires precision and expertise to achieve the desired color and shade. Silk manufacturers work with skilled dyers to create custom colors and patterns that complement the printed designs on silk turbans, adding an extra layer of depth and complexity to the final product.

In addition to printing and dyeing, silk manufacturers also play a role in the finishing process of silk turbans. Finishing techniques such as steaming, washing, and pressing are used to enhance the texture and appearance of the silk fabric, ensuring that the final product is soft, smooth, and luxurious to the touch.

| king size | 50’s neck scarf |

| rope hats | sleep cap |

| blazer scarf | kerchief |

Overall, the art of printing on silk turbans is a complex and intricate process that requires skill, expertise, and attention to detail. From selecting the right type of silk fabric to working with skilled printers and manufacturers, creating a high-quality silk turban involves a collaborative effort between designers, printers, and manufacturers. The end result is a luxurious and elegant accessory that showcases the beauty and versatility of silk fabric.